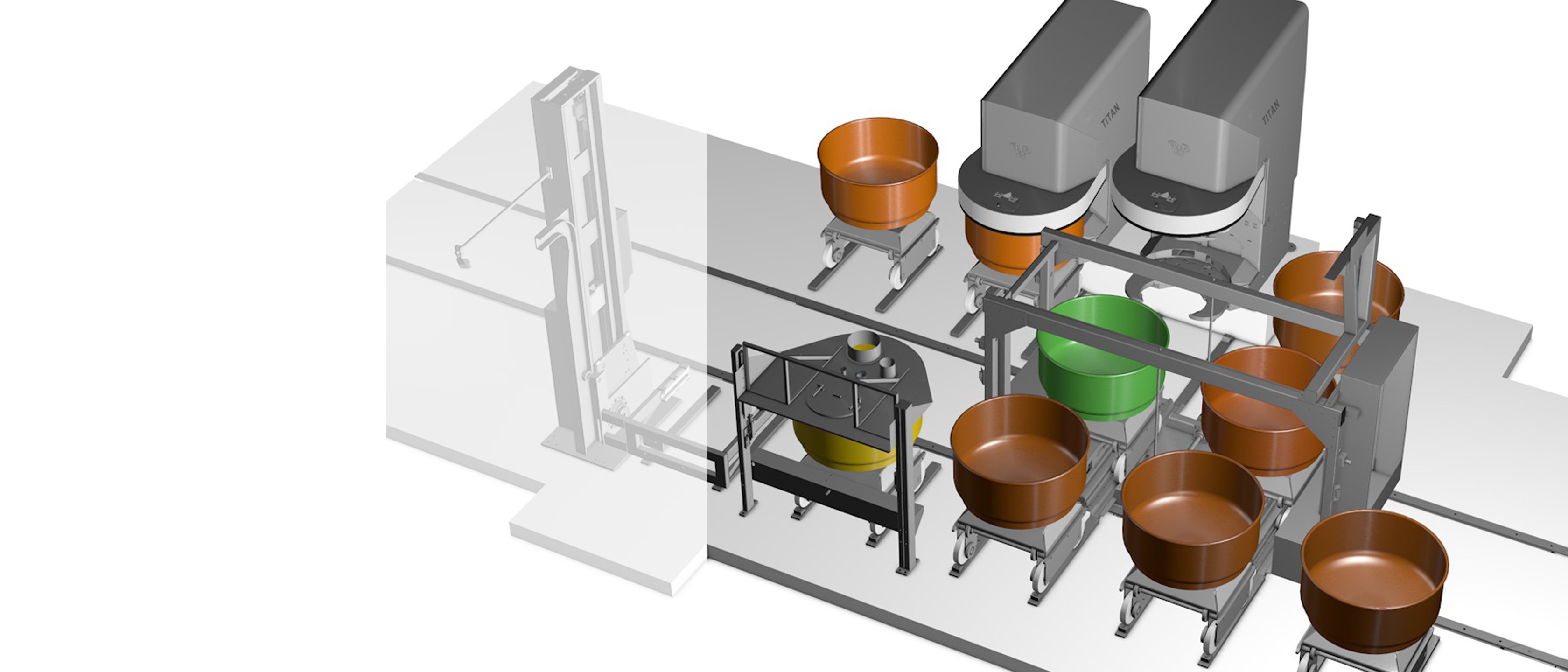

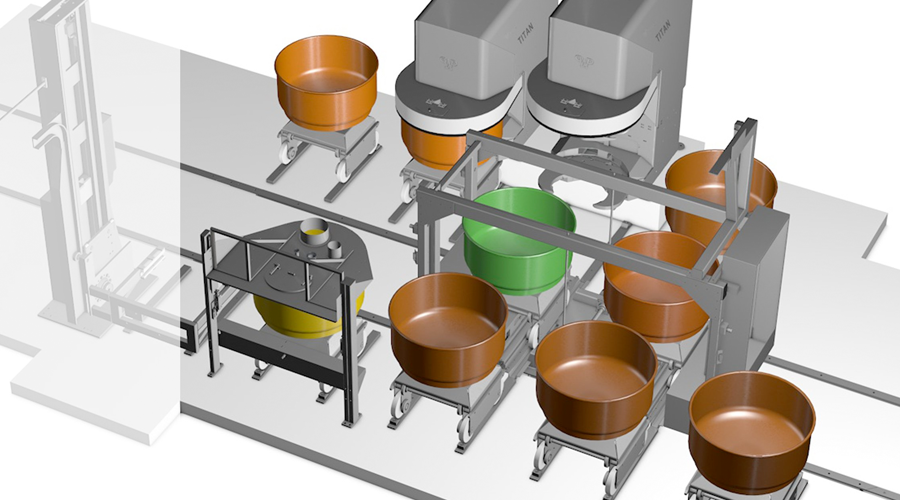

Mixing system

TITAN LINEAR

With the TITAN LINEAR SYSTEM, different resting times, a high dough output and the best dough quality can be achieved with maximum automation. The bowls are moved quickly and reliably using a carrier.

Machine variants

Advantages and benefits of the mixing system TITAN LINEAR

For a high dough quality

KEMPER 3-zone mixing principle

High oxygen input and short relaxation phases during mixing ensure particularly airy and dry doughs - even with large batches.

Capacity

Number of mixers

1-3

Dough capacity

up to 6,400 kg dough/hour

Short cycle time

up to 3,5 minutes and

the dough resting time is up to 55 minutes

Equipment and options of the mixing system TITAN LINEAR

The high-performance mixing system

We develop and build all our production lines and machines completely in our own company. The decisive performance features of our lines are their high functional reliability, their excellent profitability, and the consistently high quality of all products they make.

Product variety

High oxygenation and homogeneous doughs thanks to the 3-zone mixing principle, even at high output.

Wheat doughs

Mixed wheat doughs

Mixed rye doughs

Service and Support

We make sure that your production lines run.

Prevention

Our goal - reduce machine downtime and make them predictable through proactive maintenance.

Repairs

Faults can build up or just happen, no matter what precautions have been taken. When they do, it is vital to initiate and implement the necessary measures as soon as possible to let your lines run again.

Clean is important. Even cleaner is better. WP Clean Up

Extend the life of your machine with the machine cleaner WP CLEAN UP.