Divider and rounder

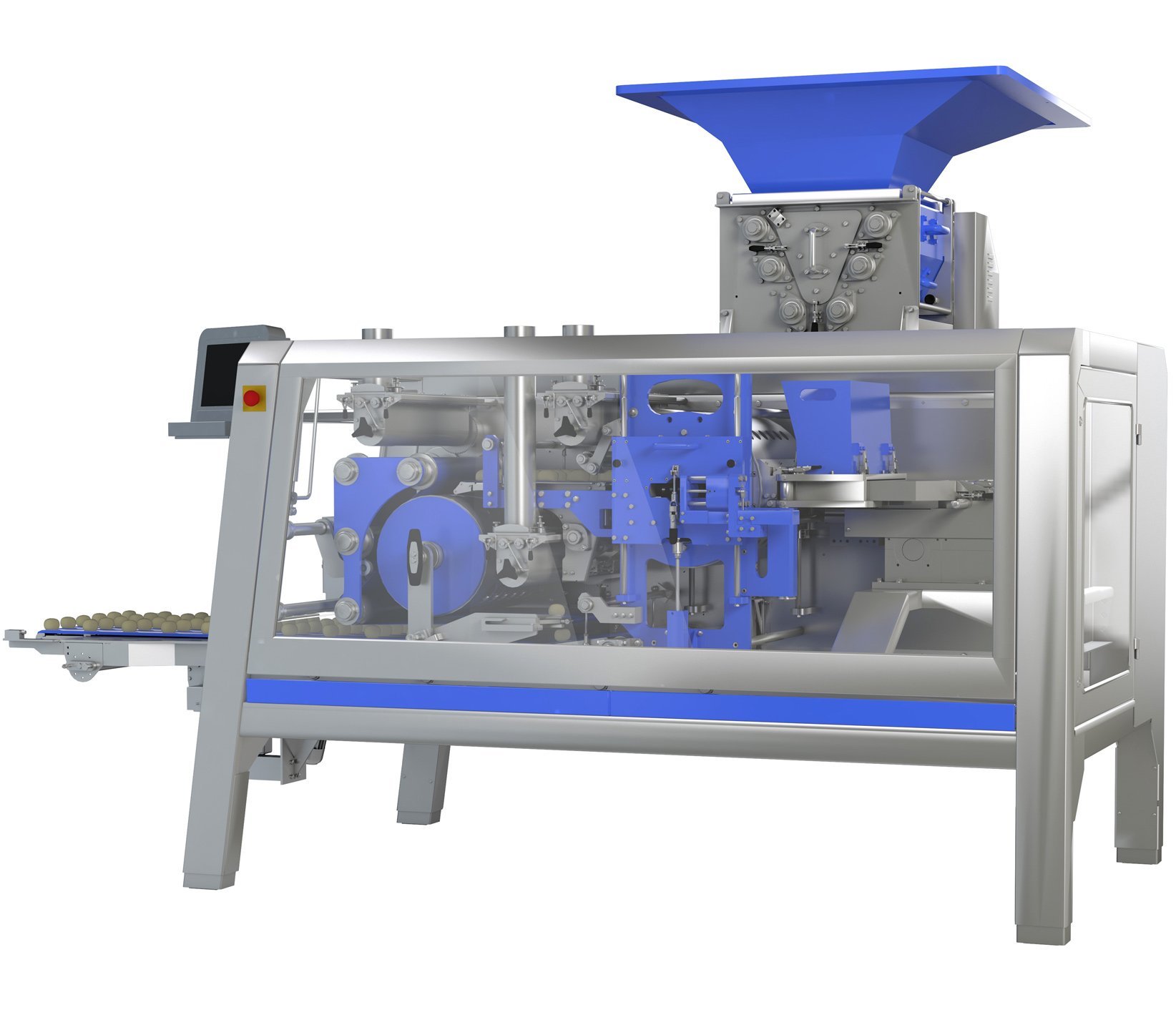

SOFT STAR CTi

We ensure highest precision in the production of rolls. Our SOFT STAR CTi ensures extremely high weight accuracy (approx. 99%) at high and highest quality and an hourly capacity of up to 57,600 dough pieces.

The maintenance and cleaning of the SOFT STAR CTi are facilitated due to the separation of the dough processing area and the drive area, as well as through the modular design of the machine. High-performance drives and a reinforced design make the SOFT STAR CTi a reliable partner in the industrial production of all kinds of rolls and buns.

Machine variants

Advantages and benefits of the head machine SOFT STAR CTi

Soft doughs extremely fast

High performance and at the same time gentle dough processing

The SOFT STAR CTi allows a high performance and at the same time gentle dough processing - this is possible due to a special process of dough feeding and conveying.

Capacity

Pieces

3.000 pieces / row

up to 57,600 pieces / hour

Tons

3, 4, 5 tons

dough throughput

Piece weight

20 - 135 g piece weight

Mono measuring drum

Piece weight

10 - 147 g piece weight

Multi measuring drum

Equipment and options of the head machine SOFT STAR CTi

For perfect dough balls

We develop and build all our production lines and machines completely in our own company. The decisive performance features of our lines are their high functional reliability, their excellent profitability, and the consistently high quality of all products they make.

Preportioner

The continuous dough feeding is done by two pairs of rollers and star rollers. The preportioner can be moved and opened tool-free for cleaning and maintenance purposes.

Intermediate hopper

Can be removed for easy cleaning and automatically locks in place once inserted.

Feeding piston

Infinitely variable pressure protects the dough. The feeding piston can also be removed for cleaning.

Measuring drum

Can be designed as a mono measuring drum with one or as a multi measuring drum with two weight ranges. A particularly high weight accuracy is achieved by a special process during the dividing process, and by using the mouthpiece, the dough is gently divided without a pressing surface. The particularly large opening of the measuring drum makes it easily accessible for cleaning.

Options

- Block off for any row or two

- Transparent intermediate hopper

- Removable intermediate belt for an easy cleaning

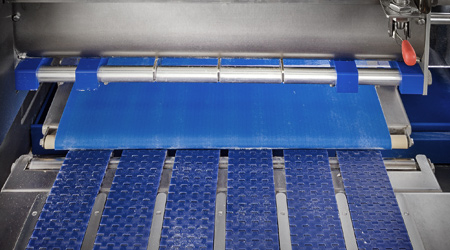

- Pressure roller and centering unit on the spreading belt attachment

- Electrically height adjustable spreading belt attachment

- KEMPER KEY access control

- Accessory trolley for storing moulding drums etc.

- Automatic lubrication of the gearbox

- Additional oiling of the dough chamber for the use of very soft doughs

- Drainage holes for the base of the drive area

Product variety

Success is a waterway as the world eats soft. The SOFT STAR CTi is particularly suitable and gentle to nearly all kind of doughs, especially very soft and sophisticated doughs, even with sensitive inclusions.

Round dough balls

Service and support

We make sure that your production lines run.

Prevention

Our goal - reduce machine downtime and make them predictable through proactive maintenance.

Repairs

Faults can build up or just happen, no matter what precautions have been taken. When they do, it is vital to initiate and implement the necessary measures as soon as possible to let your lines run again.

Clean is important. Even cleaner is better. WP Clean Up

Extend the life of your machine with the machine cleaner WP CLEAN UP.