Mixer

KRONOS

PRO

The KRONOS PRO is your reliable partner for the production of a wide variety of doughs, because we adapt the KRONOS PRO individually to your needs and those of your dough. Or do you want to mix something else? Feel free to contact us, we certainly have the right solution for that, too.

Machine variants

KRONOS 120 PRO stainless steel

120 kg dough

75 kg flour, minimum amount 7.5 kg

Bowl volume 175 l

Machine stand and control cabinet made of stainless steel

KRONOS 160 PRO stainless steel

160 kg dough

100 kg flour, minimum amount 10 kg

Bowl volume 260 l

Machine stand and control cabinet made of stainless steel

KRONOS 200 PRO stainless steel

200 kg dough

125 kg flour, minimum amount 12.5 kg

Bowl volume 300 l

Machine stand and control cabinet made of stainless steel

KRONOS 240 PRO stainless steel

240 kg dough

150 kg flour, minimum amount 15 kg

Bowl volume 350 l

Machine stand and control cabinet made of stainless steel

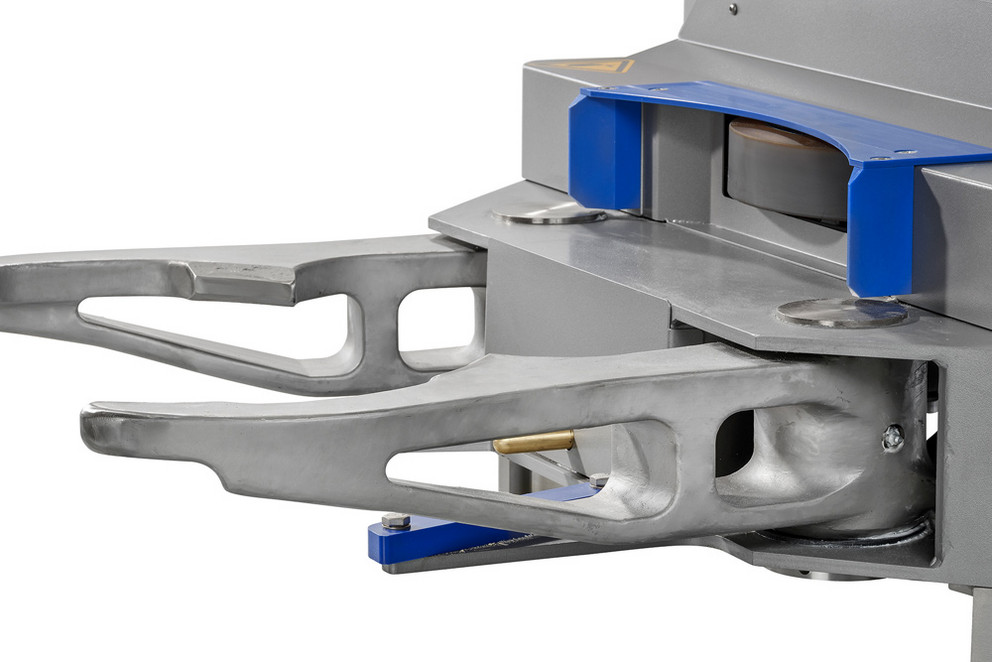

Advantages and benefits of the

wheel-out spiral mixer KRONOS PRO

Everything starts with good dough

KEMPER 3-zone mixing principle

Adds more oxygen to the dough, producing soft, easy to process doughs in reproducible quality.

Capacity

Flour

75 - 150 kg

Dough

120 - 240 kg

Equipment and options of the

wheel-out spiral mixer KRONOS PRO

For a reproducible dough quality

The name Kemper has always been synonymous with mixing and dough processing. Worldwide. For more than 100 years. We have continuously developed and refined our mixers, and have repeatedly brought new, innovative mixers and mixing systems onto the market – a success story based on proven technologies.

Options

- Temperature sensor PT 100

- Program control with Touch Panel

- Multi-Phase control with Touch Panel

- Rotation counter

- KEMPER KEY access control

- Data interface for the connection to a higher-level control system

- Bowl identification via RFID

- Pastry tool

- Pretzel tool

- Rye tool

- Bowl with drain screw

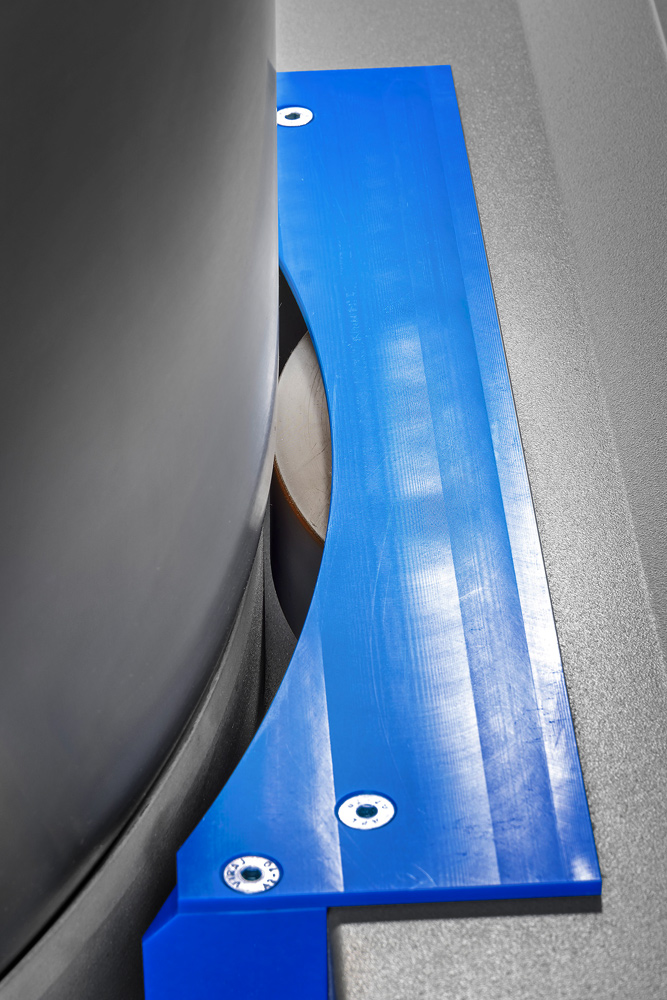

- Bowl scraper

- Separate control cabinet

Product variety

The KRONOS PRO mixer is optimally designed for flexible use in bakeries. It meets the highest demands on versatility and easy handling. Alongside the classic spiral tools, a wide array of special tools are available for individual dough requirements. These are used e.g. to reduce mixing times or dough temperature increase.

Wheat doughs

Mixed wheat doughs

Mixed rye doughs

Rye doughs

Service and support

We make sure that your production lines run.

Prevention

Our goal - reduce machine downtime and make them predictable through proactive maintenance.

Repairs

Faults can build up or just happen, no matter what precautions have been taken. When they do, it is vital to initiate and implement the necessary measures as soon as possible to let your lines run again.

Clean is important. Even cleaner is better. WP Clean Up

Extend the life of your machine with the machine cleaner WP CLEAN UP.