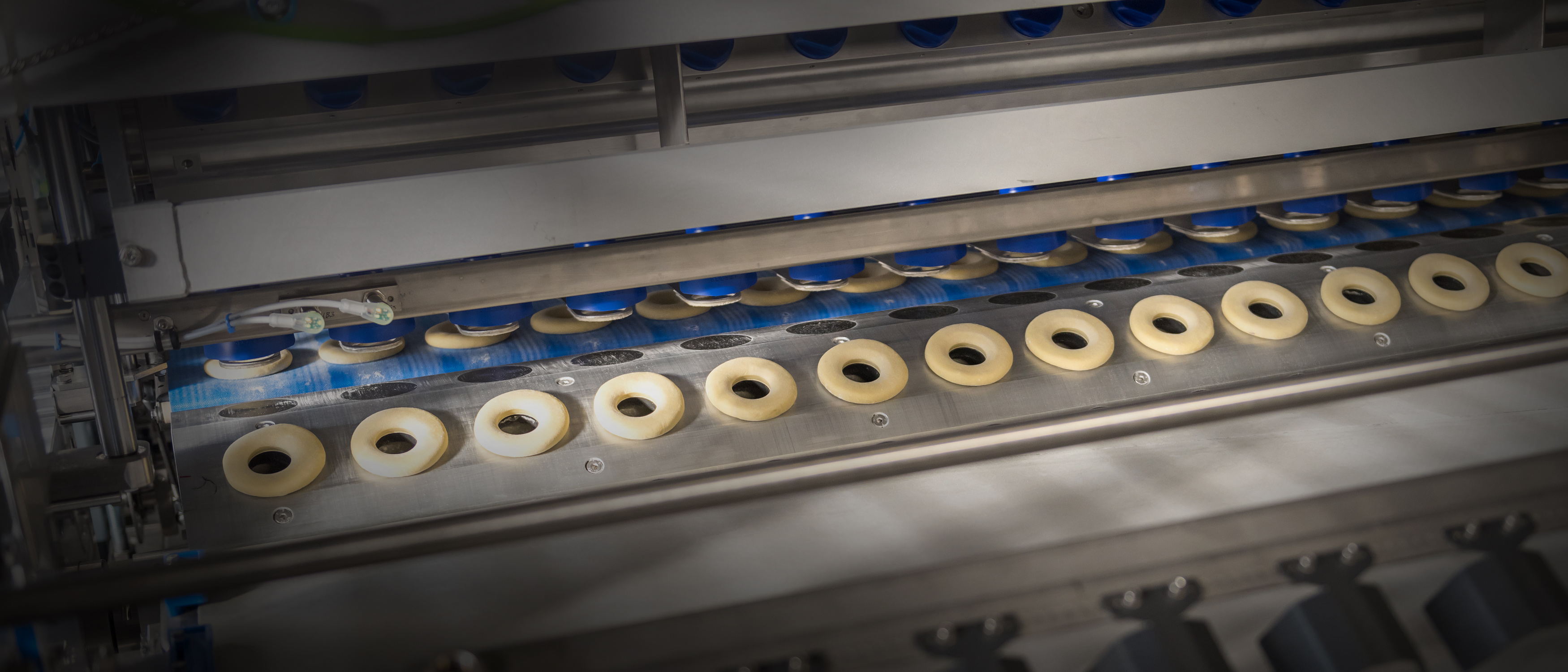

Donut line

EVOLUTION DONUT LINE

The WP Kemper EVOLUTION DONUT LINE is perfectly aligned for the production of ring and ball donuts. The decisive performance features of our systems are their high functional reliability, their excellent profitability and the consistently high quality of all products they make. Our systems work with the KEMPER DOUGH BALL SYSTEM whose central component is our patented donut stamp.

Machine variants

EVOLUTION DONUT & BERLINER LINE

Rows: 6 - 16

Pieces/hour: up to 57,600

Weight range: 10 g - 70 g

Working width: 800 mm, 1,000 mm, 1,200 mm

For the production of donuts and ball donuts

EVOLUTION BERLINER LINE

Rows: 6 - 16

Pieces/hour: up to 57,600

Weight range: 10 g - 70 g

Working width: 800 mm, 1,000 mm, 1,200 mm

For the production of ball donuts

Advantages and benefits of the EVOLUTION DONUT LINE

For high quality donuts and ball donuts

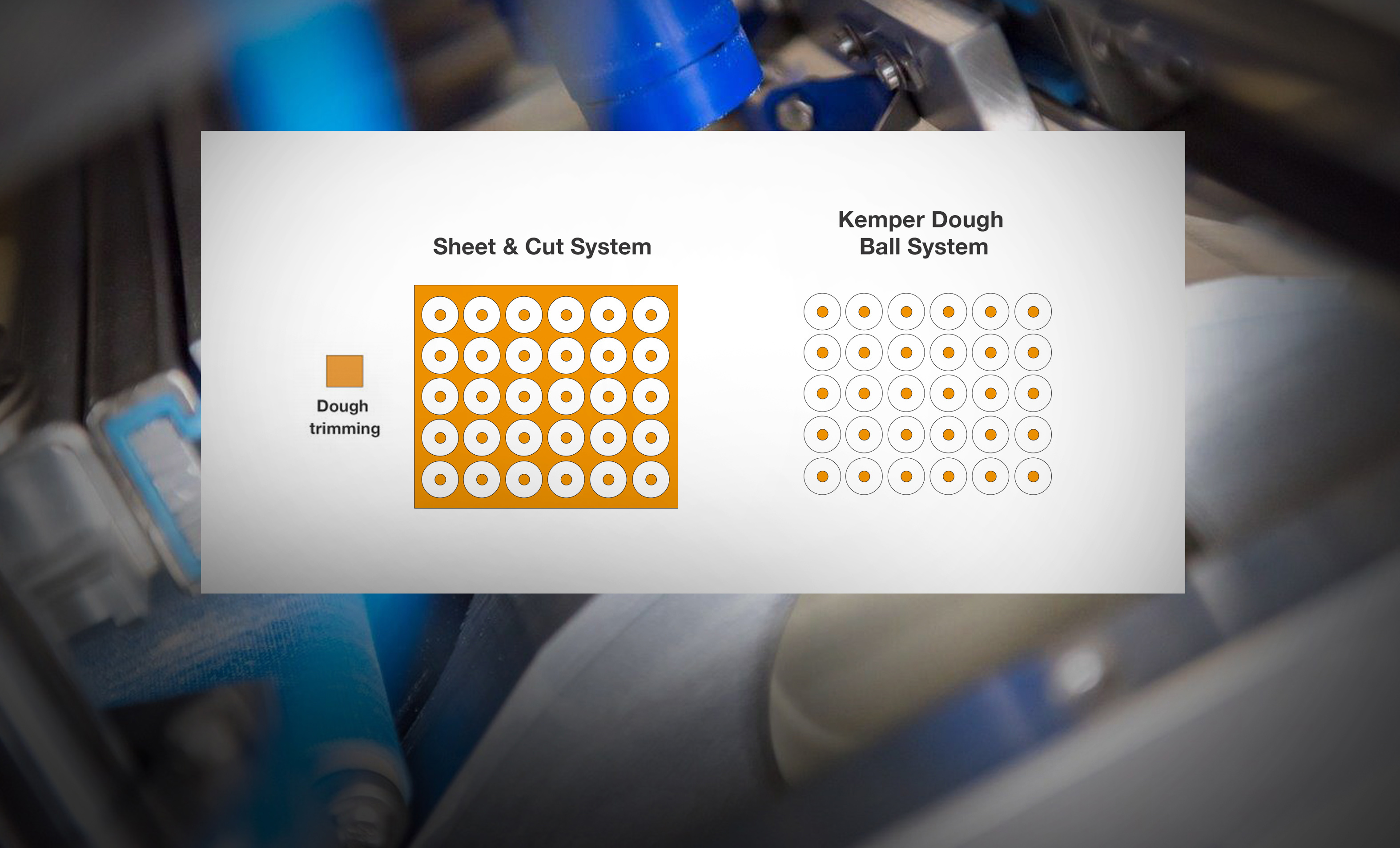

Patented donut stamp

The low scrap dough quantity due to the patented donut stamp can be optimally used for further dough batches without reducing the quality of the donut. The production from a round piece gives the donuts and ball donuts a perfect round shape

Capacity

Pieces

up to 57,600 pieces / hour

Weight range

Weight range 10 g - 70 g / higher weights depending on product diameter

Rows

6 - 16 rows and working width 800 mm, 1,000 mm, 1,200 mm

Equipment and options of the EVOLUTION DONUT LINE

High value donut production

We develop and build all our production lines and machines completely in our own company. The decisive performance features of our lines are their high functional reliability, their excellent profitability, and the consistently high quality of all products they make.

Dough dividing and moulding machine SOFT STAR CTi

The SOFT STAR CTi produces dough balls very precisely and gently with fine pore structure and an even, dry surface.

Intermediate proofer

The flat base of the trays enables a dimensionally stable proofing of the pre-formed dough pieces. The optional hygiene station maintains the hygiene standards in the product touching area.

Final proofer

Gentle discharge from the final proofer and direct transfer of the dough pieces into the fryer. The final proofer is equipped with changeable tray inserts. To maintain the hygiene standard, a tray cleaning station, consisting of rotating brushes and infra-red technology, can be added. An insulation housing ensures a uniform, manageable climate within the final proofer.

Product variety

Numerous products can be produced with the modular DONUT & BERLINER LINE. True to the motto "think process", the system can be extended to a fully automatic donut and ball donut production system

Mini ball donuts

Mini donuts

Ball donuts (sugared)

Ball donuts (glazed, chocolate)

Donuts (frosted)

Donuts (sugared)

Long donuts

Service and support

We make sure that your production lines run.

Prevention

Our goal - reduce machine downtime and make them predictable through proactive maintenance.

Repairs

Faults can build up or just happen, no matter what precautions have been taken. When they do, it is vital to initiate and implement the necessary measures as soon as possible to let your lines run again.

Clean is important. Even cleaner is better. WP Clean Up

Extend the life of your machine with the machine cleaner WP CLEAN UP.