Roll line

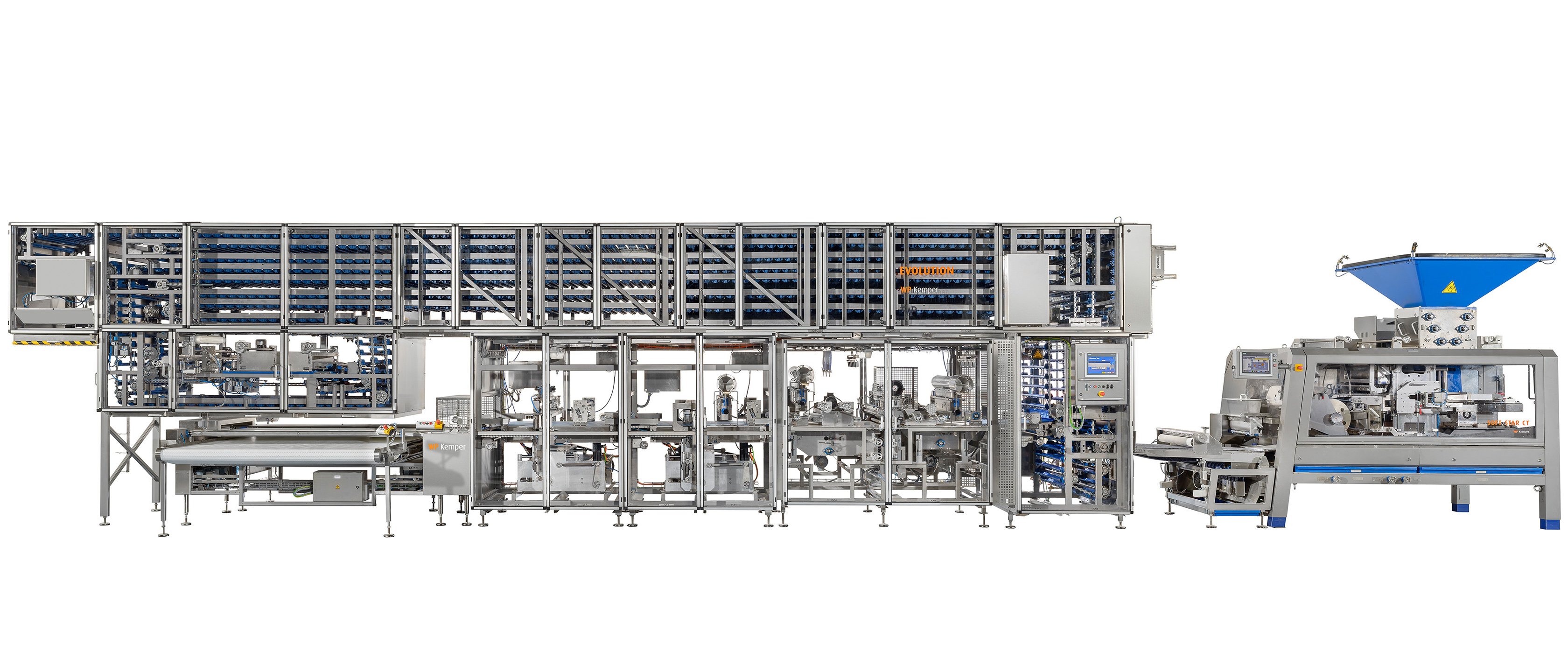

EVOLUTION

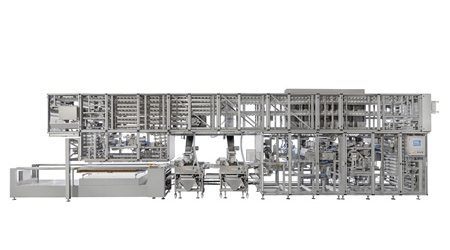

The knowledge of the requirements of our customers and technical expertise are the basis for our modular roll line EVOLUTION. Our focus is on the exact processing of products as well as on the efficient response to seasonal and long-term market changes. EVOLUTION is a modular line concept for today and for every future - extremely flexible, powerful and at the same time energy-optimized.

Machine variants

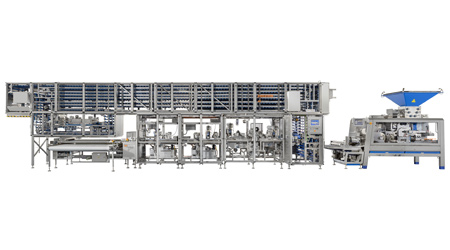

EVOLUTION LINE

Rows: 6 -12

Pieces/hour: 12.000 - 43,200

Weight range: 25 - 140 g

Working width: 800 mm, 1.000 mm, 1.200 mm

For a complete intermediate proof

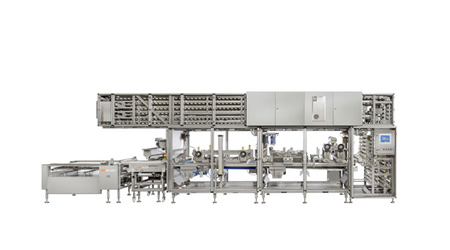

EVOLUTION COMPACT

Rows: 6 -12

Pieces/hour: 12.000 - 43,200

Weight range: 25 - 140 g

Working width: 800 mm, 1.000 mm, 1.200 mm

For a divided intermediate proof

Advantages and benefits of the roll line EVOLUTION

For a safe production

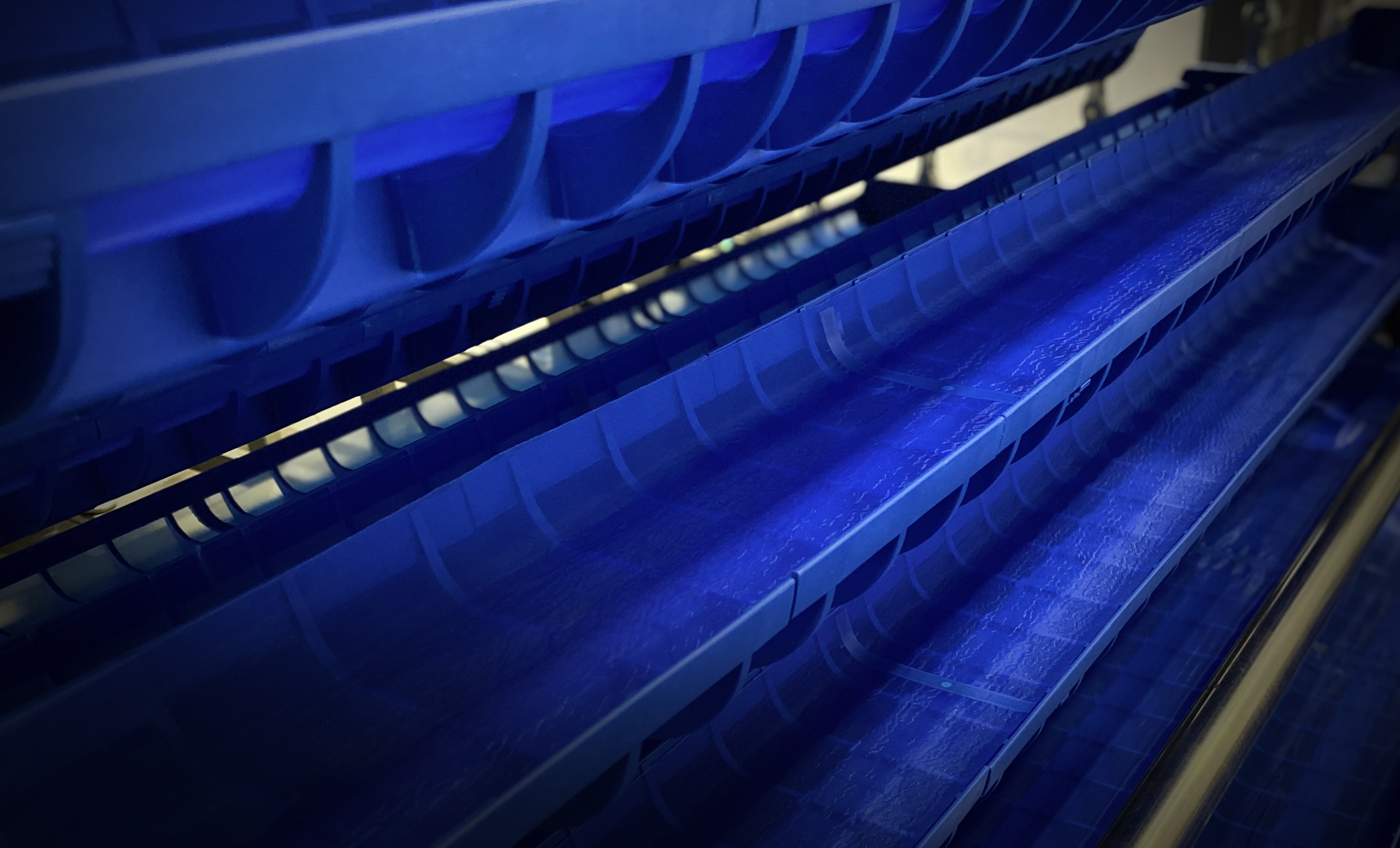

Easy maintenance of the hygienic level

due to washable, air permeable gauze inserts.

Capacity

Pieces

12,000 - 43,200 pieces / hour

Weight range

Weight range 25 - 140 g

Rows

6 -12 rows and Working width 800 mm, 1,000 mm, 1,200 mm

Equipment and options of the roll line EVOLUTION

For high quality rolls

We develop and build all our production lines and machines completely in our own company. The decisive performance features of our lines are their high functional reliability, their excellent profitability, and the consistently high quality of all products they make.

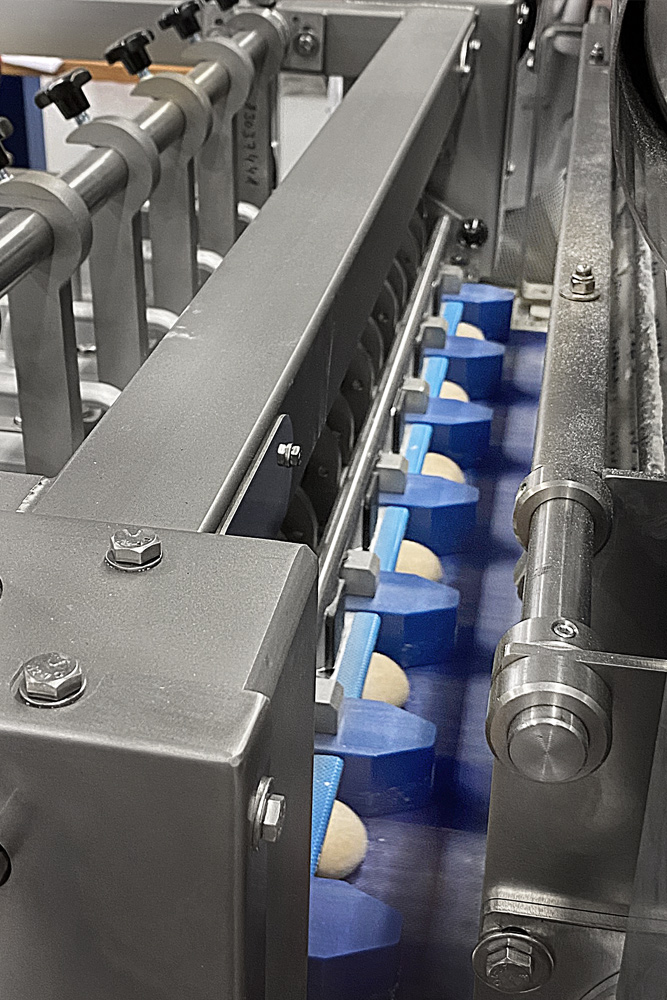

Trays

Plastic trays with removable and washable gauze inserts for a good ventilation of the dough pieces. The tray chains have low-maintenance requirements.

Options

- ISO housing and air conditioning for the proofer

- Hygiene station with infra-red emitters (replaces UV sterilization)

- Hygiene station Plus with infra-red emitters (replaces UV sterilization) and tray cleaning station

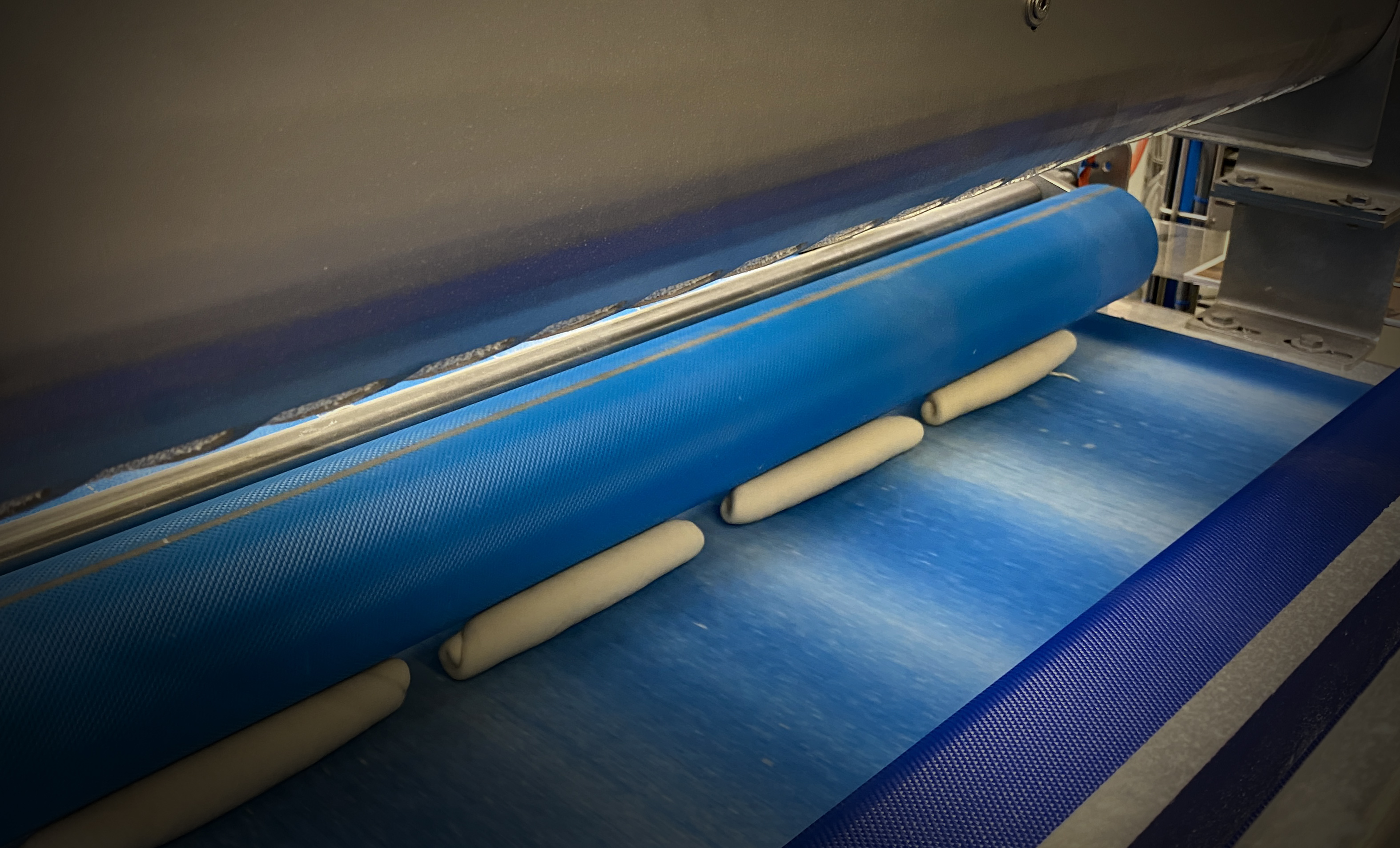

- Longmoulding modules

- Longmoulding module with upper belt to produce seamless longmoulded products

- Pinning and curling longmoulding module to produce pinned and longmoulded products with up to two curls

- Sheeting and curling longmoulding module to produce sheeted and longmoulded products with up to four curls

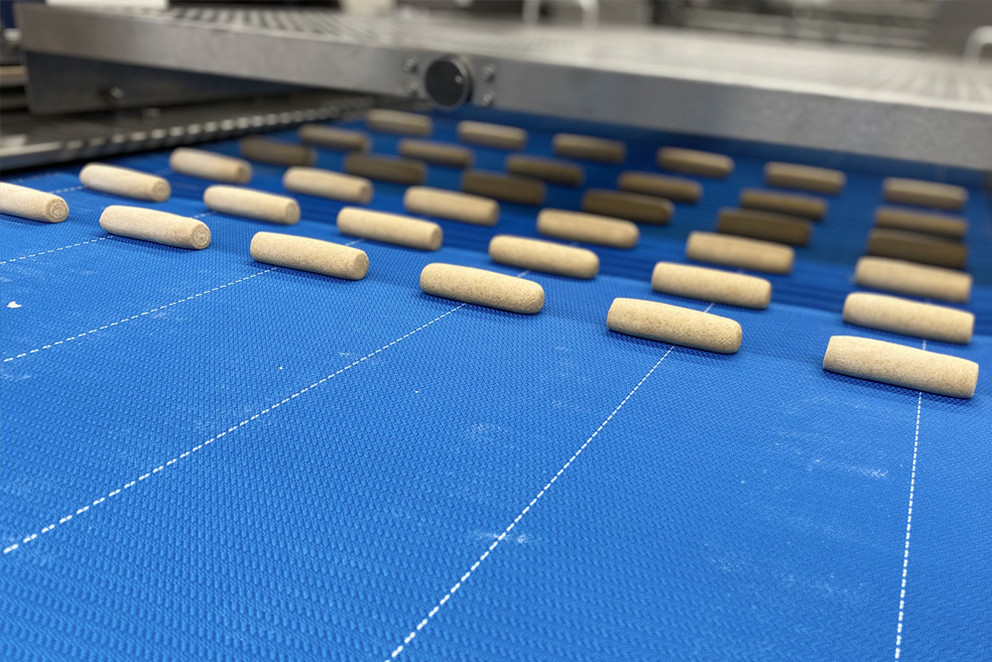

- Longmoulding module with moulding channels to produce cylindrical, longmoulded products

- Cutting module to produce slit rolls

- Double roll module to produce two round pieces pressed together

- Stamping module on the belt to produce stamped rolls

- Stamping module with trays to produce stamped rolls like Kaiser rolls

- Passau oiling station for a second moulding with fat

- Wachauer module for a second moulding with flour

- Seeding module for automatically seeding one side of the dough piece

- Reciprocating belt for the automatic depositing onto trays, belts and tray conveying systems

- Tray conveying system

- KEMPER KEY access control

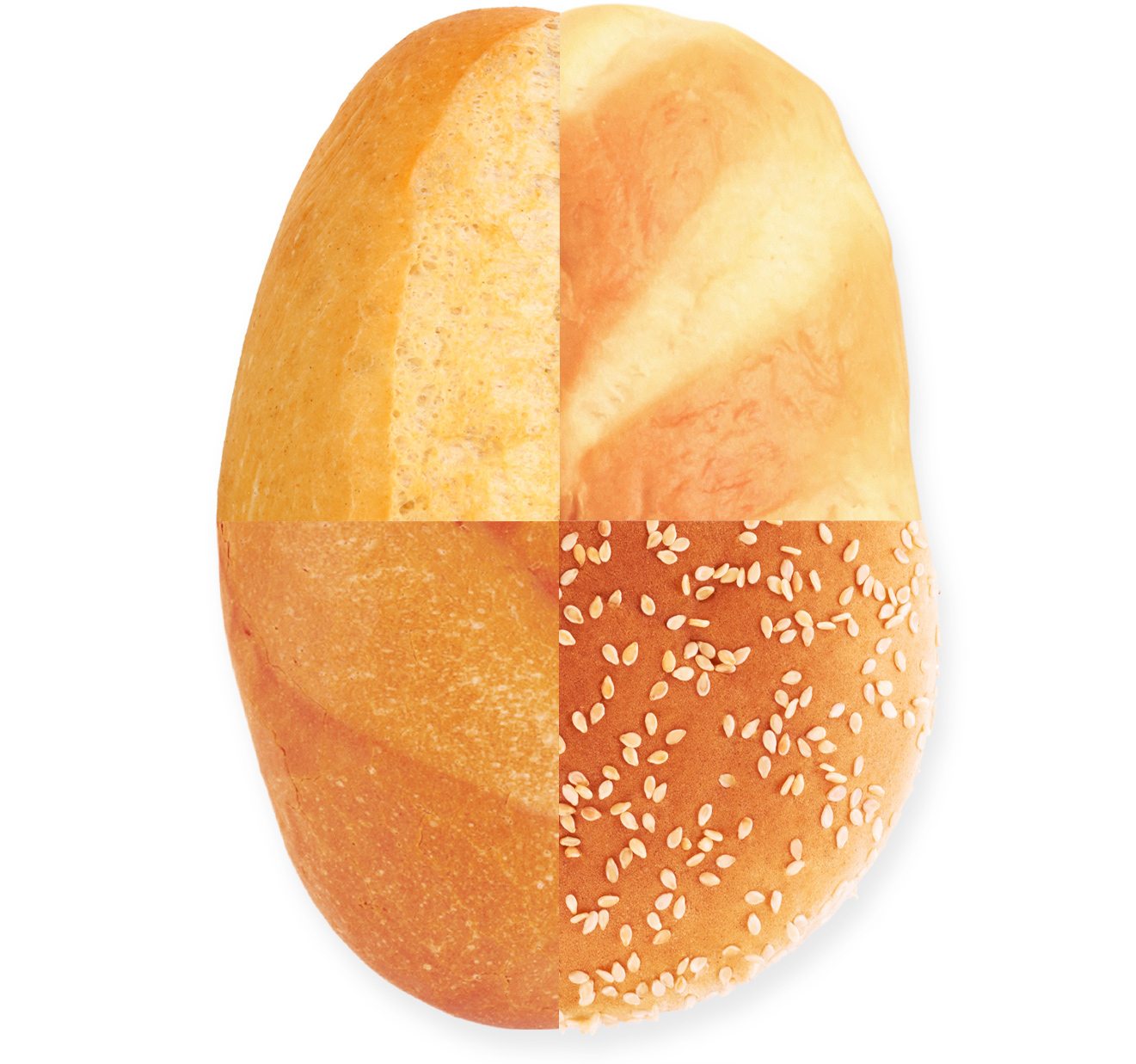

Product variety

Precise processing and especially gentle to the dough. This is possible by the combination of SOFT STAR CTi head maschine and EVOLUTION roll line. The combination of various modules allows the

production of versatile products.

Crusty

Turnkey process solutions up to 36,000 pcs./h | Process example for slit rolls and kaiser rolls.

moreSweet & Soft

Turnkey process solutions up to 36,000 pcs./h | Process example for hamburger buns, briochette, hot dog buns and pain au lait.

moreFlexy

Turnkey process solutions up to 36,000 pcs./h | Process example for round, longmoulded, stamped, flat pressed, folded and curled rolls.

moreHamburger- & Hotdog-Buns

Complete production processes specialized for hamburger buns and hot dog buns consist of coordinated components that enable the efficient and continuous production of baked goods.

more

Slit rolls

Kaiser rolls

Roundmoulded rolls

Stamped rolls

Hamburger buns

Hot Dog buns

Sandwiches / Finger rolls

Folded rolls

Longmoulded rolls

Service and Support

We make sure that your production lines run.

Prevention

Our goal - reduce machine downtime and make them predictable through proactive maintenance.

Repairs

Faults can build up or just happen, no matter what precautions have been taken. When they do, it is vital to initiate and implement the necessary measures as soon as possible to let your lines run again.

Clean is important. Even cleaner is better. WP Clean Up

Extend the life of your machine with the machine cleaner WP CLEAN UP.